Klaus Union

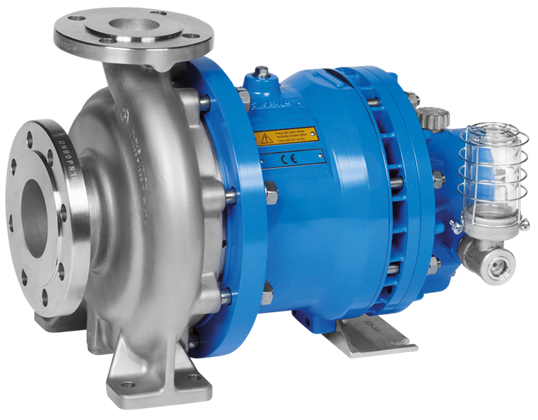

Klaus Union is a globally recognized manufacturer specializing in sealless magnetic drive pump technology for critical and hazardous process applications. Headquartered in Germany, Klaus Union has built its reputation on leak-free pump designs, a modular engineering platform, and long-term reliability in demanding chemical, petrochemical, energy, and industrial services.

The company focuses on applications where process safety, containment, and operational reliability are essential, offering sealless solutions as an alternative to conventional shaft-sealed pumps.

Core Technologies & Capabilities

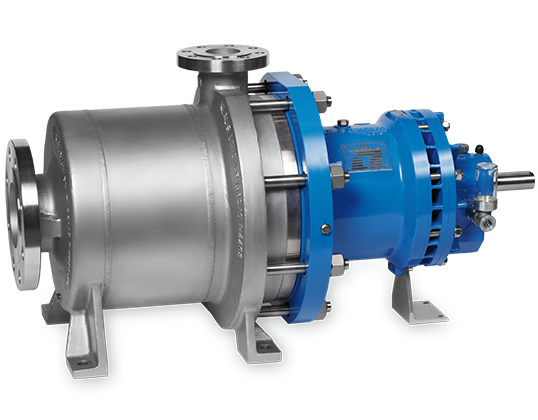

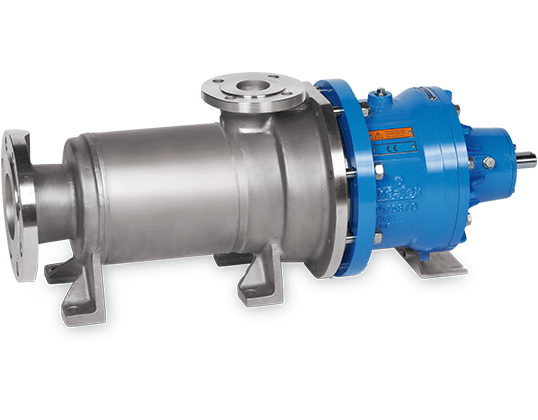

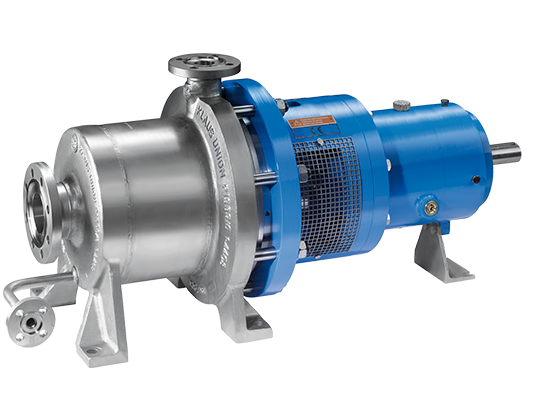

- Sealless magnetic drive centrifugal pumps (horizontal and vertical designs)

- API 685 heavy-duty sealless process pumps

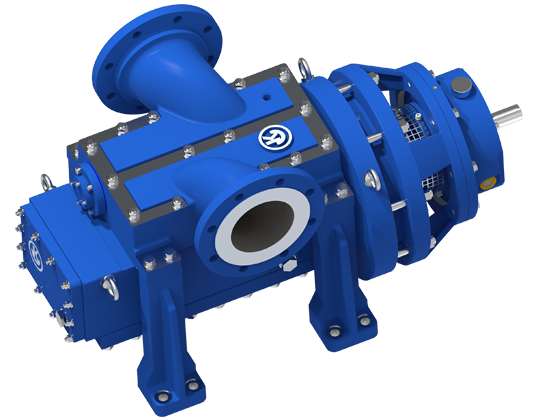

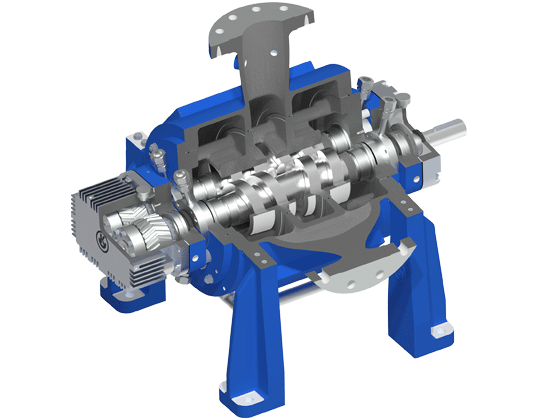

- Sealless twin screw pumps (API 676) for challenging process duties

- Modular system concept enabling component standardization and lifecycle efficiency

Typical Applications

Standards & Design Philosophy

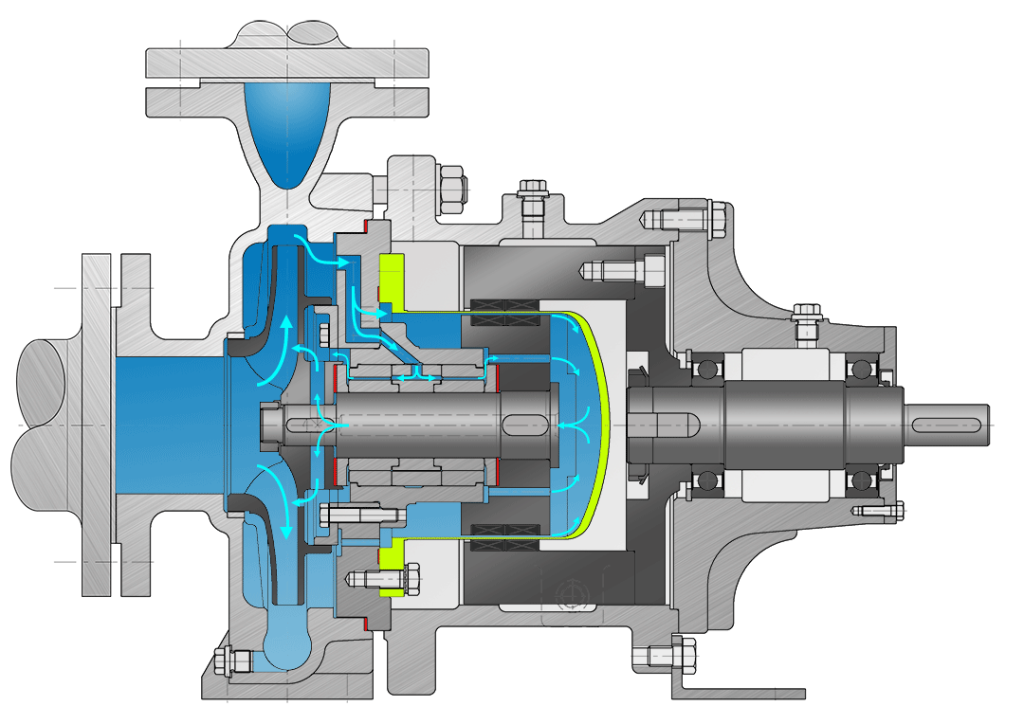

Magnetic drive technology:

Klaus Union magnetic drive/magnetic coupling technology offers distinct long- and short-term advantages over conventional sealing system.

This technology does a way with a need for shaft to pass from liquid to non-liquid environments which means that glands and face seal can be dispensed with. The liquid is hermetically sealed in a leakproof, static isolation shell.

SEALLESS TECHNOLOGY

If pumps are used to handle dangerous products, it is essential to avoid even the smallest leakages into the environment in order to ensure the protection of both people and the atmosphere. The ideal solution for such a case is pumps with magnet drive. The first of its kind was introduced by Klaus Union in 1955.

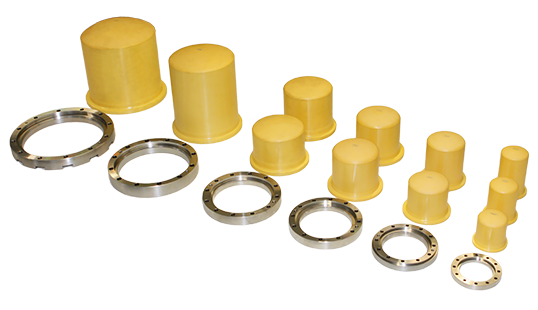

Klaus Union Extensive Product Portfolio:

Klaus Union product portfolio comprises pumps and valves for virtually all industrial applications. In addition to steel and stainless steel, Klaus Union products integrate numerous corrosion-proof alloys based on Ni-Cr-Fe, Ni-Cr-Fe-Mo, nickel and titanium.

Klaus Union pumps and valves offer optimal safety and reliability, as well as a long service life, and reduce costs thanks to their maintenance friendliness for the following application scenarios: chemical and petrochemical industry; refrigeration and heat engineering; liquid gas plants; electroplating; power plants; and plant construction.

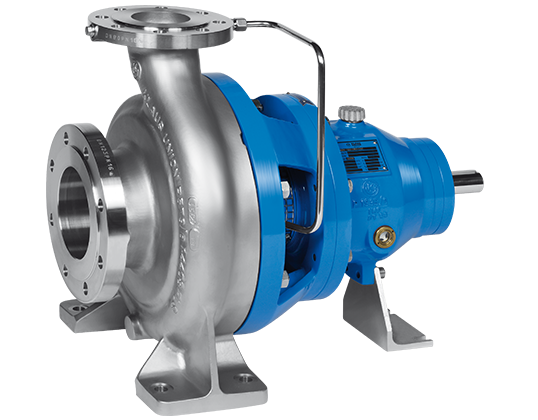

Single-Stage – DIN EN ISO

Flow Rate : up to 3.500 m³/h

Delivery Head: up to 220 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: up to PN 400

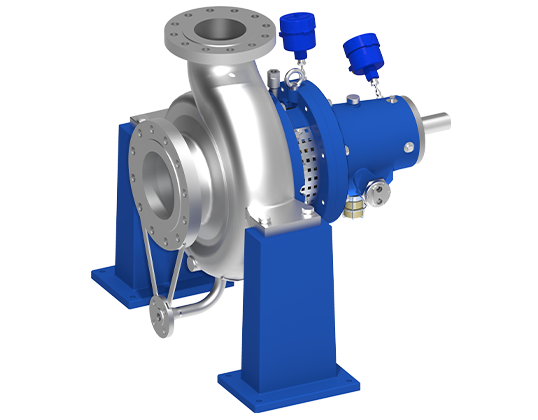

Single-Stage – API

Flow Rate : max. 3.500 m³/h

Delivery Head: max. 220 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: max. PN 400

Single-Stage – ASME

Flow Rate : up to 150 m³/h

Delivery Head: up to 100 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: up to PN 400

High Temperature Applications

Flow Rate : max. 1.200 m³/h

Delivery Head: max. 215 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: max. PN 40

Multi-Stage – DIN EN ISO / API

Flow Rate : max. 300 m³/h

Delivery Head: max. 2.200 m L.C.

Temperature Range: -120 °C to +350 °C

Pressure Rating: max. PN 250

Side Channel Pump – DIN EN ISO

Flow Rate : max. 42 m³/h

Delivery Head: max. 470 m L.C.

Temperature Range: -120 °C to +250 °C

Pressure Rating: max. PN 400

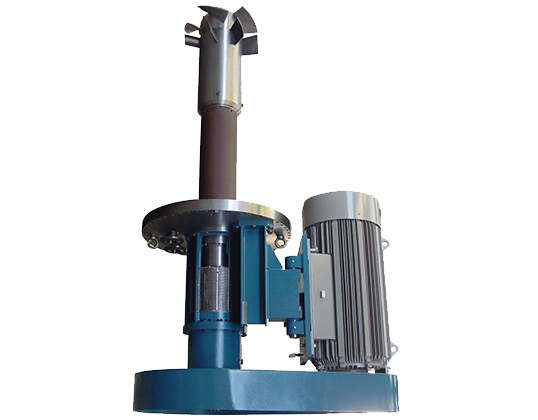

Submerged Pumps – DIN EN ISO / API / ASME

Flow Rate : up to 900 m³/h

Delivery Head: up to 200 m L.C.

Temperature Range: -40 °C up to +200 °C

Pressure Rating: up to PN 40

ENERGY EFFICIENT DESIGN

Transmittable Power: up to 1 MW

Temperature Range: -200 °C to +400 °C

Pressure Rating: max. PN63

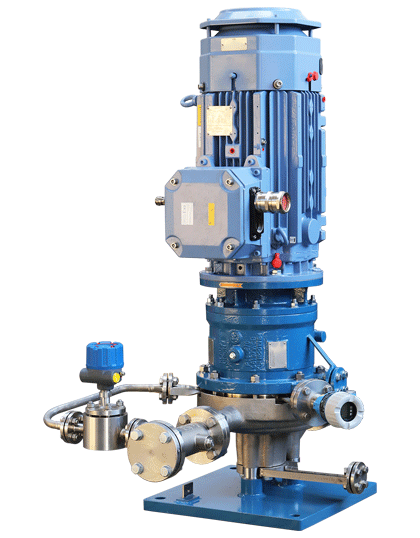

Vertical Inline Pumps – DIN EN ISO / API / ASME

Flow Rate : up to 900 m³/h

Delivery Head: up to 220 m L.C.

Temperature Range: -120 °C up to +350 °C

Pressure Rating: PN 40 at 120 °C

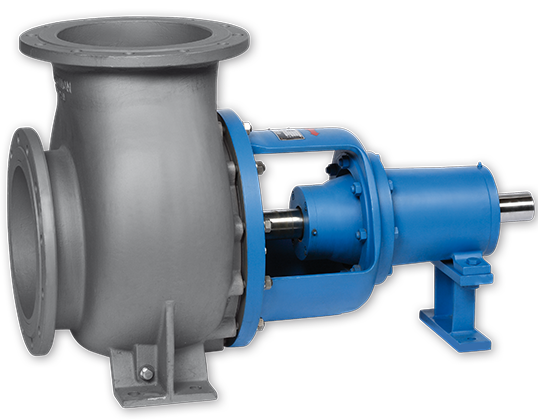

Single-Stage – DIN EN ISO

Flow Rate : max. 3.500 m³/h

Delivery Head:up to 220 m L.C.

Temperature Range: -120 °C up to +450 °C

Pressure Rating: max 400 PN

Single-Stage – API

Flow Rate : up to 3.500 m³/h

Delivery Head:up to 220 m L.C.

Temperature Range: -120 °C up to +450 °C

Pressure Rating: PN 40 @ 120 °C

Multi-Stage – DIN EN ISO / API & ISO

Flow Rate : max. 300 m³/h

Delivery Head:max. 2.200 m L.C.

Temperature Range: -120 °C to +350 °C

Pressure Rating: max. 250 PN

Submerged Pumps – DIN EN ISO / API & ISO

Flow Rate : max. 1.600 m³/h

Delivery Head: max. 200 m L.C.

Temperature Range: -50 °C to +250 °C

Pressure Rating: max. PN 40

Propeller Pumps

Flow Rate : max. 12.000 m³/h

Delivery Head:max. 12 m L.C.

Temperature Range: -120 °C to +250 °C

Pressure Rating: max. 100 PN

Lower-Flange Propeller Pump

Flow Rate : max. 21.500 m³/h

Delivery Head:max. 8,5 m L.C.

Temperature Range: -50 °C to +400 °C

Pressure Rating: max. 10 PN

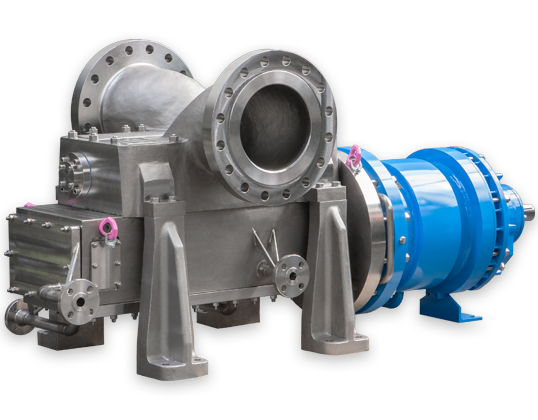

Single Volute – API

Flow Rate : max. 1.800 m³/h

Differential Pressure:max. 40 bar

Temperature Range: -120 °C to +350 °C

Pressure Rating: max 400 PN

Single Volute – API

Flow Rate : max. 1.800 m³/h

Differential Pressure:max. 40 bar

Temperature Range: -120 °C to +350 °C

Pressure Rating: max 400 PN

Double Volute – API

Flow Rate : max. 5.000 m³/h

Differential Pressure:max. 100 bar

Temperature Range: -120 °C to +350 °C

Viscosity: max. 100.000 mPas