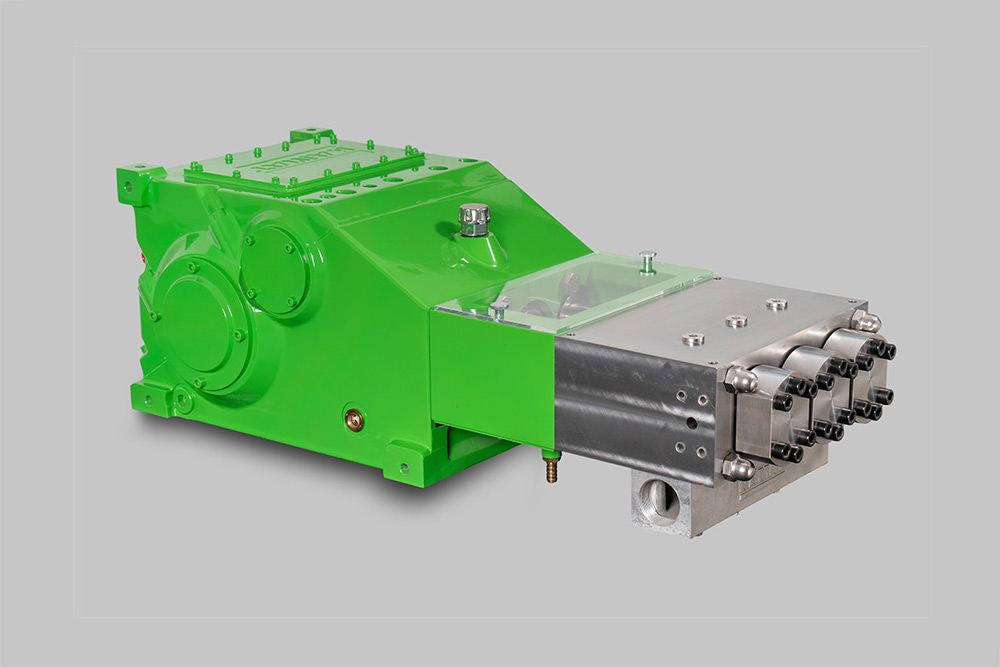

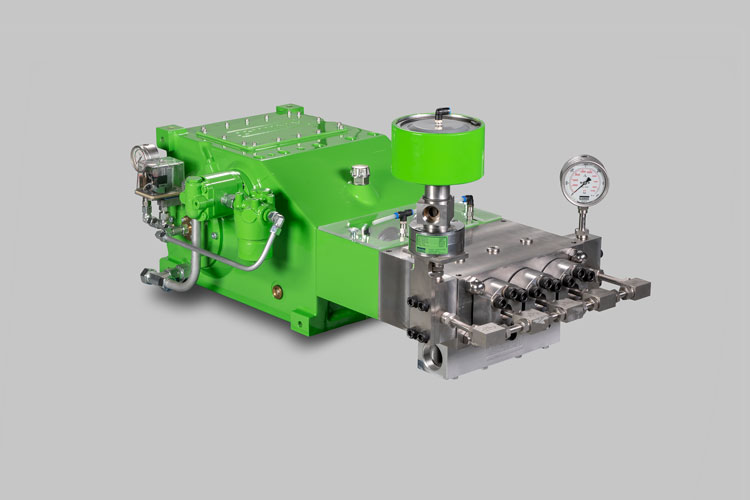

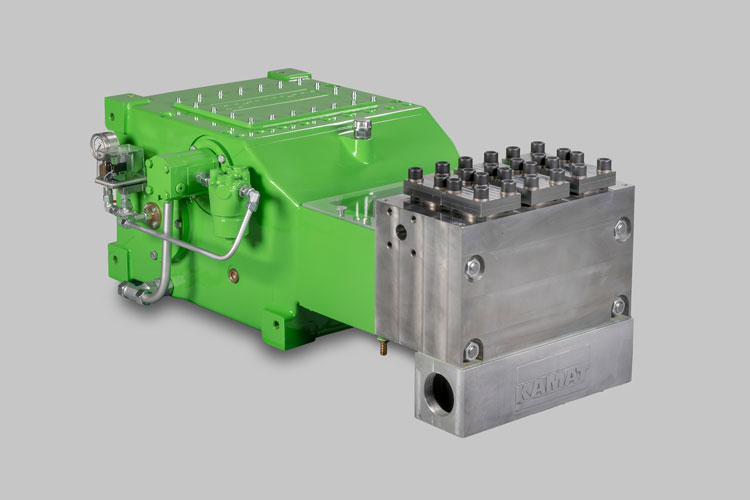

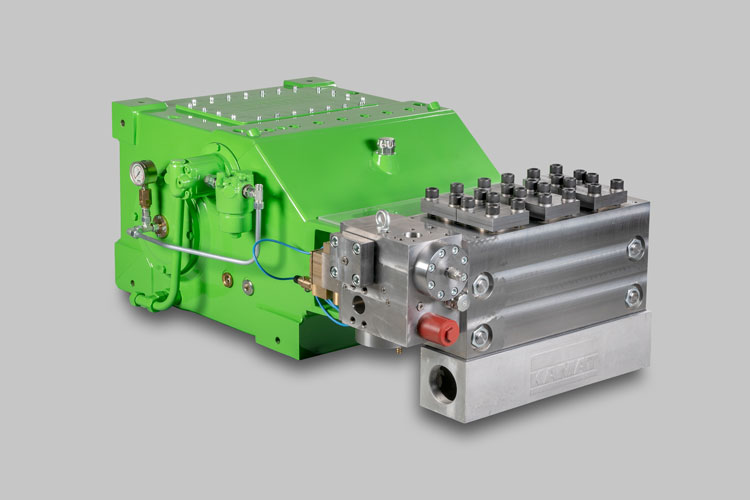

KAMAT

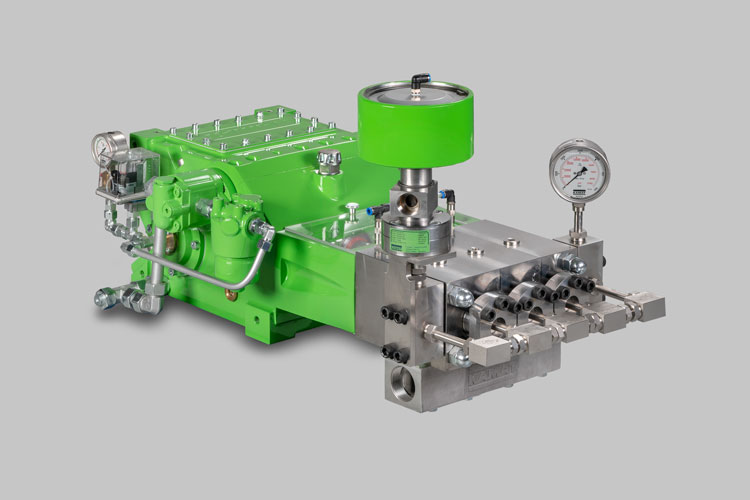

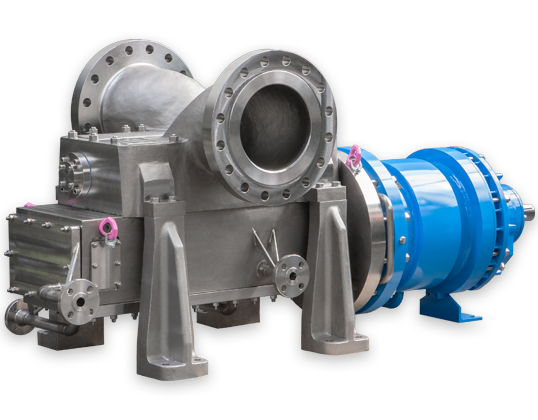

For more than 40 years KAMAT have been specialized in one thing: High-pressure applications and solutions. KAMAT develops and produces high-pressure plunger pumps and complex pump systems, as well as complete high-pressure systems, including pump accessories and high-pressure accessories – always at the most detailed manufacturing level. KAMAT’s high-pressure pumps perform up to 1500 kW and 3.500 bar and can be specified in hundreds of variants to suit all customer needs.

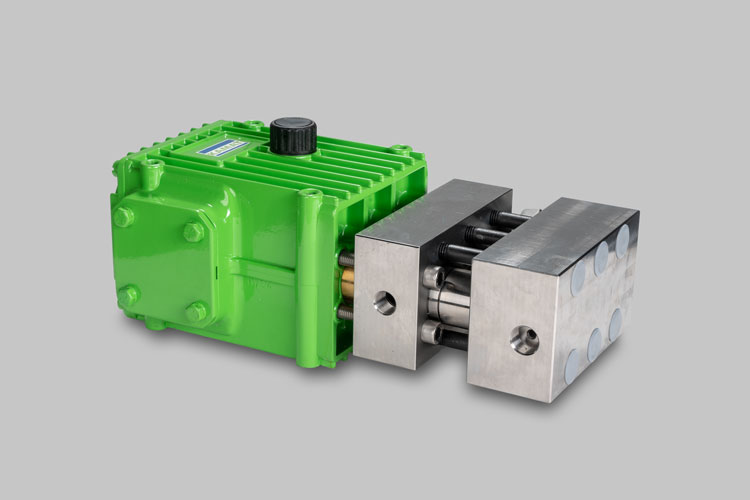

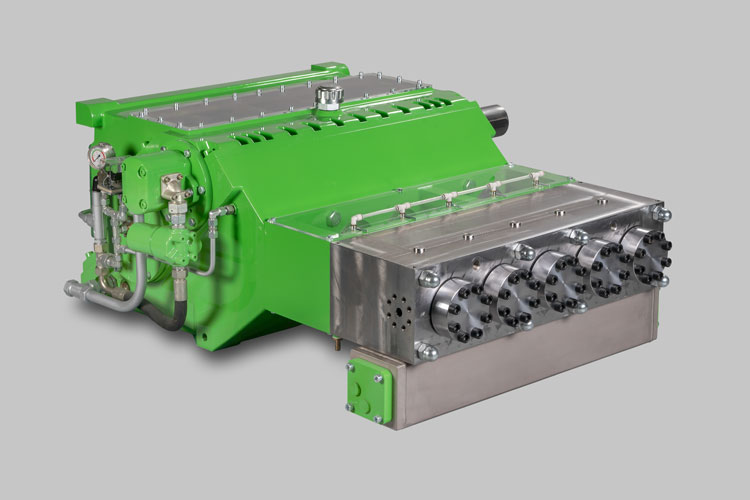

K55000-5G

max. 3500 bar

max. 1913 I/min

max. 550 kW

max. 2200 kg

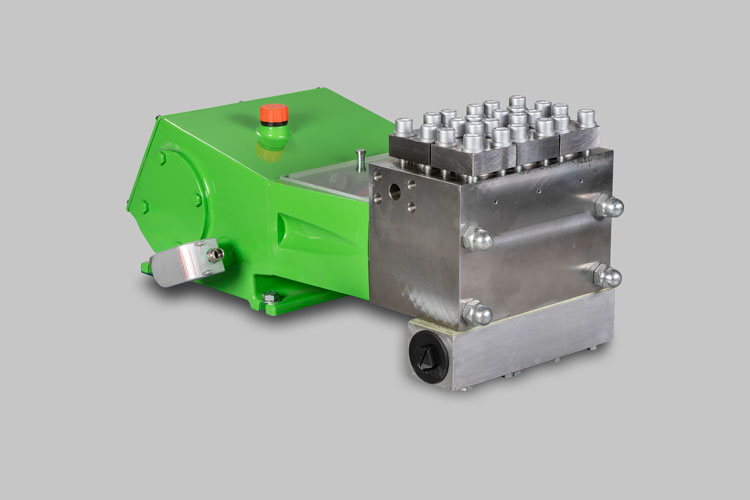

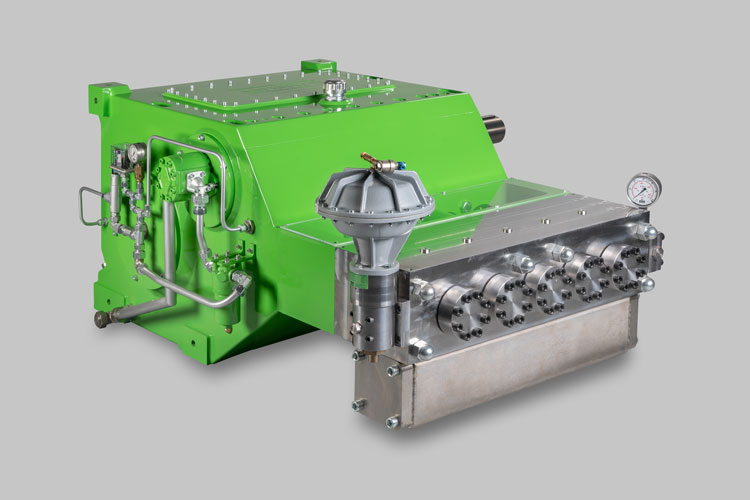

K100000-5G

max. 3500 bar

max. 3482 I/min

max. 1000 kW

max. 3650 kg

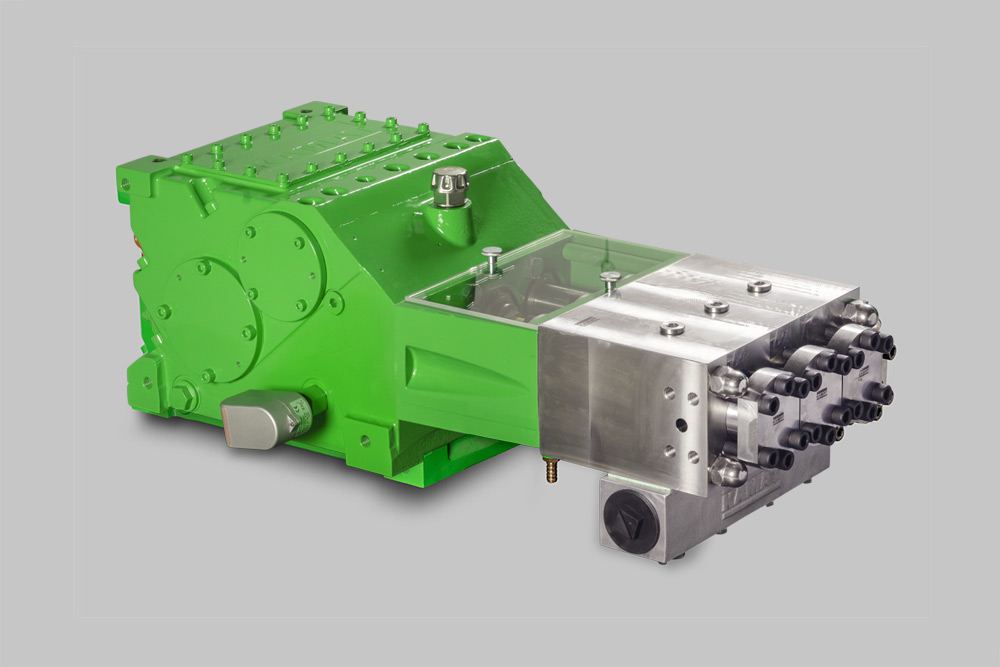

K150000-5G

max. 3500 bar

max. 4677 I/min

max. 1500 kW

max. 7500 kg

Industries with Water Hydraulics and High-Pressure Applications

Aquaculture

High-pressure units for inshore and offshore based aquaculture

Chemistry and Petrochemistry

High-pressure anduUltra-high-pressure pumps successful as individual solution for processes in the chemical and petrochemical industries

Construction Industry

KAMAT high-pressure solutions for jetting, concrete removal and restauration, descaling and paint removal from all surfaces

Energy Sector

High-pressure technology in the energy sector – a powerful partnership

Food Industry

KAMAT ultra-high-pressure solutions for the food industry – cleaning of tanks, vessels and pipelines with high-pressure jets

Industrial High-Pressure Cleaning

Cleaning, removal of paint, or other coatings, with high-pressure technology

Mining

Bergbauhydraulik – KAMAT Plungerpumpen und Hochdruck-Pumpensysteme im Bergbau für den Einsatz unter Tage

Oil and Gas Industry

High-pressure pumps for sensitive media and fluids containing solid particles

Paper Industry

KAMAT high-pressure technology for paper industry

Pharma Industry

Ultra-high-pressure for the pharmaceutical industry

Process Industry

Safe pumping of corrosive, abrasive and volatile fluids like Ammonia

Ship Industry and Shipyards

High-pressure technology for naval industries and shipyards

Steel Industry

High-pressure technology by KAMAT ideal for the steel industry – perfectly equipped for descaling, force-fed lubrication, and water hydraulics

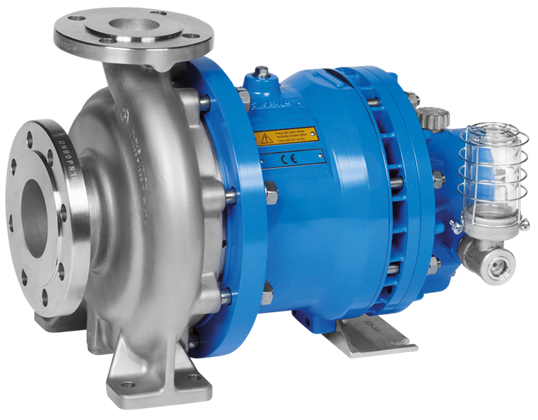

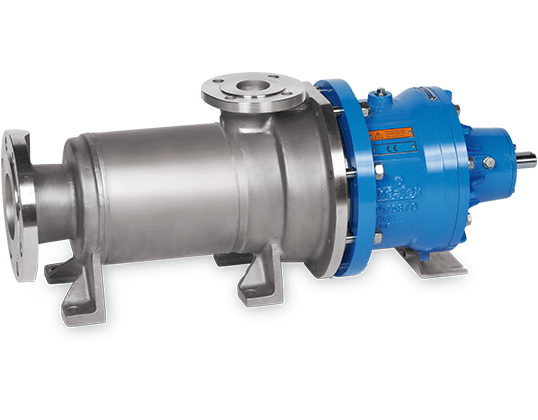

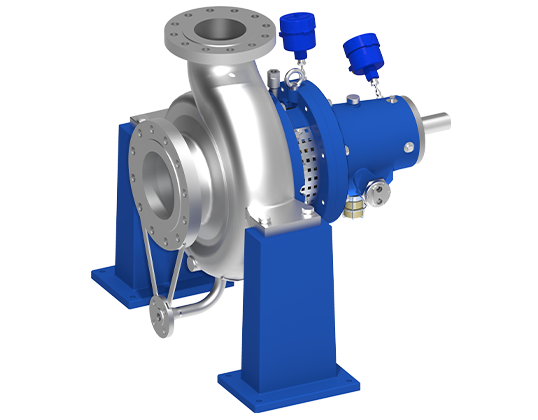

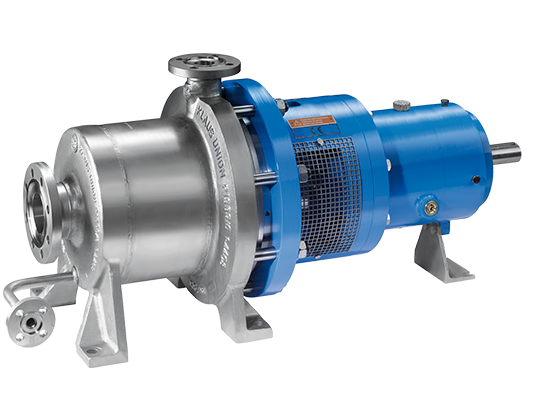

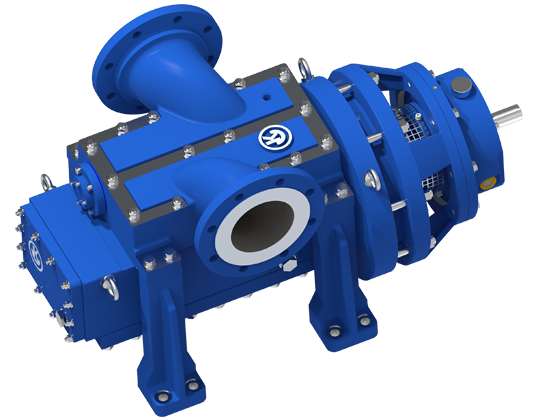

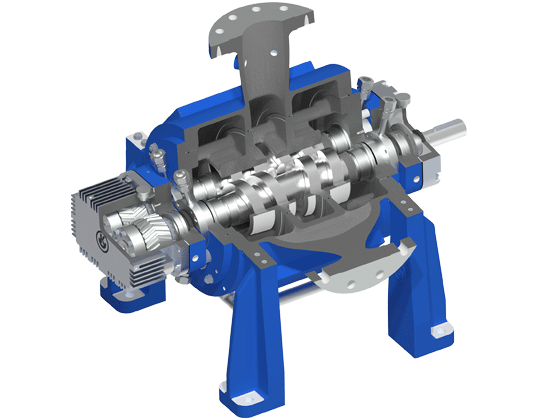

Klaus Union

Since 1946 Klaus Union is a market leader in the development of pumps and valves that meet the most exacting quality requirements. Klaus Union’s products are used to transport aggressive, toxic and explosive substances in the chemical and petrochemical industries.

- Leading worldwide specialist in the market of industrial pumps and valves. The chemical and petrochemical industries make extensive use of our magnetica drive technology

- Since their incorporation 70 years ago, Klaus Union has acquired a well-deserved reputation as a leading magnet drive pumps

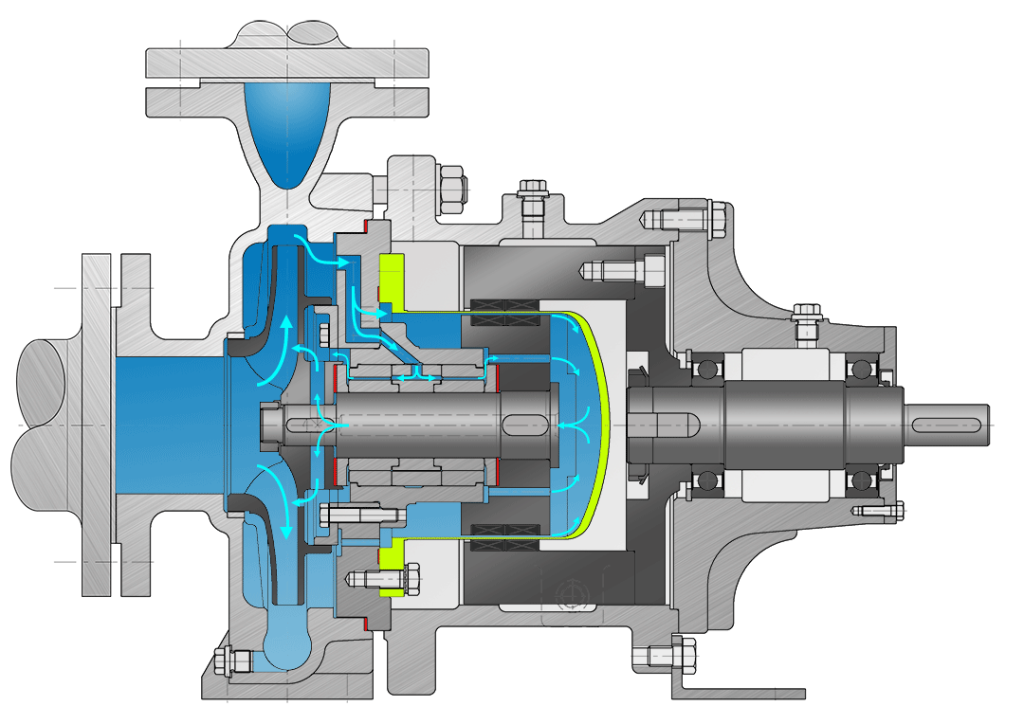

Magnetic drive technology:

Klaus Union magnetic drive/magnetic coupling technology offers distinct long- and short-term advantages over conventional sealing system.

This technology does a way with a need for shaft to pass from liquid to non-liquid environments which means that glands and face seal can be dispensed with. The liquid is hermetically sealed in a leakproof, static isolation shell.

SEALLESS TECHNOLOGY

If pumps are used to handle dangerous products, it is essential to avoid even the smallest leakages into the environment in order to ensure the protection of both people and the atmosphere. The ideal solution for such a case is pumps with magnet drive. The first of its kind was introduced by Klaus Union in 1955.

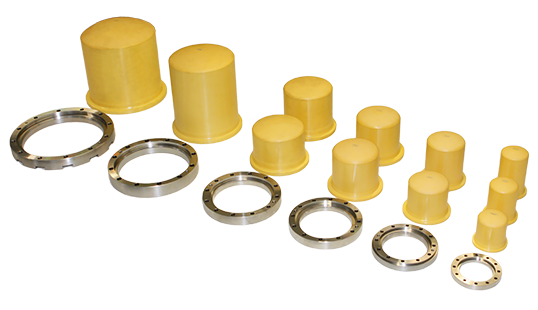

Klaus Union Extensive Product Portfolio:

Klaus Union product portfolio comprises pumps and valves for virtually all industrial applications. In addition to steel and stainless steel, Klaus Union products integrate numerous corrosion-proof alloys based on Ni-Cr-Fe, Ni-Cr-Fe-Mo, nickel and titanium.

Klaus Union pumps and valves offer optimal safety and reliability, as well as a long service life, and reduce costs thanks to their maintenance friendliness for the following application scenarios: chemical and petrochemical industry; refrigeration and heat engineering; liquid gas plants; electroplating; power plants; and plant construction.

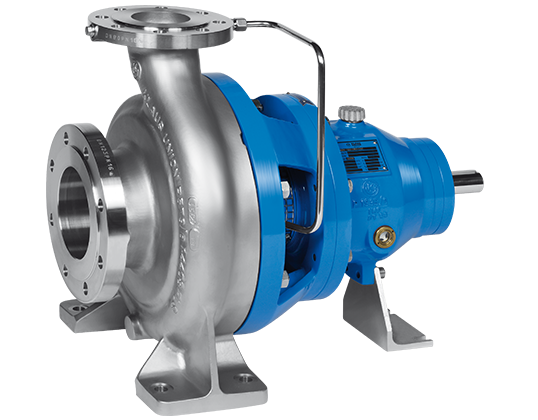

Single-Stage – DIN EN ISO

Flow Rate : up to 3.500 m³/h

Delivery Head: up to 220 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: up to PN 400

Single-Stage – API

Flow Rate : max. 3.500 m³/h

Delivery Head: max. 220 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: max. PN 400

Single-Stage – ASME

Flow Rate : up to 150 m³/h

Delivery Head: up to 100 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: up to PN 400

High Temperature Applications

Flow Rate : max. 1.200 m³/h

Delivery Head: max. 215 m L.C.

Temperature Range: -120 °C to +450 °C

Pressure Rating: max. PN 40

Multi-Stage – DIN EN ISO / API

Flow Rate : max. 300 m³/h

Delivery Head: max. 2.200 m L.C.

Temperature Range: -120 °C to +350 °C

Pressure Rating: max. PN 250

Side Channel Pump – DIN EN ISO

Flow Rate : max. 42 m³/h

Delivery Head: max. 470 m L.C.

Temperature Range: -120 °C to +250 °C

Pressure Rating: max. PN 400

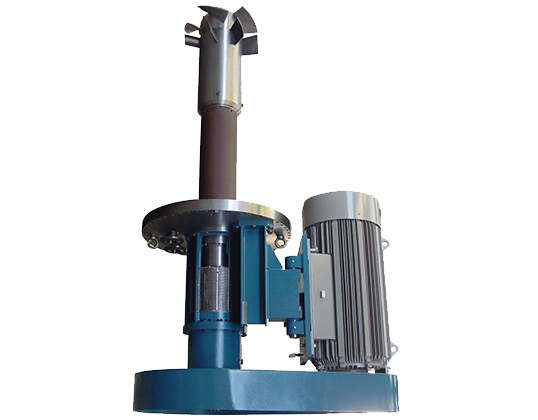

Submerged Pumps – DIN EN ISO / API / ASME

Flow Rate : up to 900 m³/h

Delivery Head: up to 200 m L.C.

Temperature Range: -40 °C up to +200 °C

Pressure Rating: up to PN 40

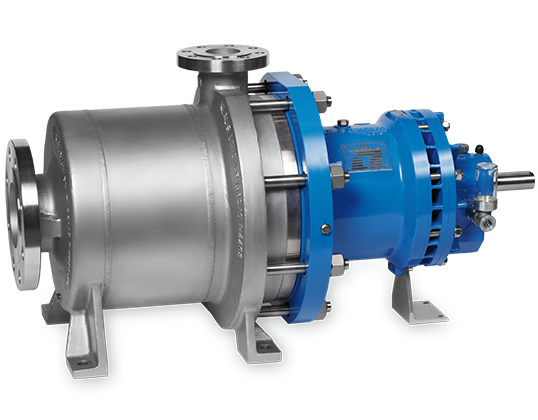

ENERGY EFFICIENT DESIGN

Transmittable Power: up to 1 MW

Temperature Range: -200 °C to +400 °C

Pressure Rating: max. PN63

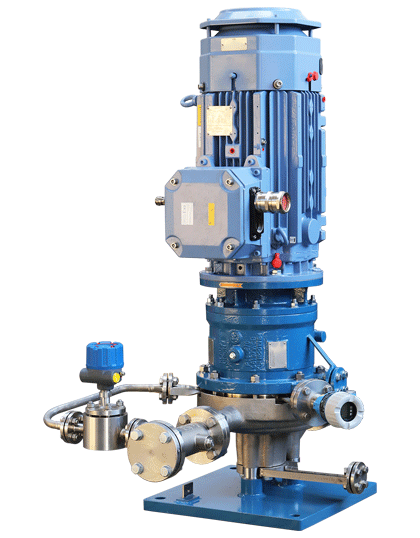

Vertical Inline Pumps – DIN EN ISO / API / ASME

Flow Rate : up to 900 m³/h

Delivery Head: up to 220 m L.C.

Temperature Range: -120 °C up to +350 °C

Pressure Rating: PN 40 at 120 °C

Single-Stage – DIN EN ISO

Flow Rate : max. 3.500 m³/h

Delivery Head:up to 220 m L.C.

Temperature Range: -120 °C up to +450 °C

Pressure Rating: max 400 PN

Single-Stage – API

Flow Rate : up to 3.500 m³/h

Delivery Head:up to 220 m L.C.

Temperature Range: -120 °C up to +450 °C

Pressure Rating: PN 40 @ 120 °C

Multi-Stage – DIN EN ISO / API & ISO

Flow Rate : max. 300 m³/h

Delivery Head:max. 2.200 m L.C.

Temperature Range: -120 °C to +350 °C

Pressure Rating: max. 250 PN

Submerged Pumps – DIN EN ISO / API & ISO

Flow Rate : max. 1.600 m³/h

Delivery Head: max. 200 m L.C.

Temperature Range: -50 °C to +250 °C

Pressure Rating: max. PN 40

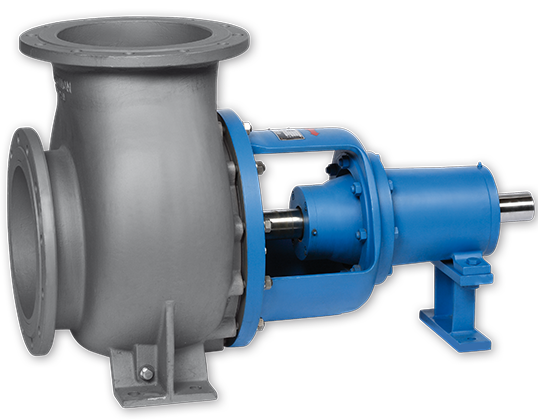

Propeller Pumps

Flow Rate : max. 12.000 m³/h

Delivery Head:max. 12 m L.C.

Temperature Range: -120 °C to +250 °C

Pressure Rating: max. 100 PN

Lower-Flange Propeller Pump

Flow Rate : max. 21.500 m³/h

Delivery Head:max. 8,5 m L.C.

Temperature Range: -50 °C to +400 °C

Pressure Rating: max. 10 PN

Single Volute – API

Flow Rate : max. 1.800 m³/h

Differential Pressure:max. 40 bar

Temperature Range: -120 °C to +350 °C

Pressure Rating: max 400 PN

Single Volute – API

Flow Rate : max. 1.800 m³/h

Differential Pressure:max. 40 bar

Temperature Range: -120 °C to +350 °C

Pressure Rating: max 400 PN

Double Volute – API

Flow Rate : max. 5.000 m³/h

Differential Pressure:max. 100 bar

Temperature Range: -120 °C to +350 °C

Viscosity: max. 100.000 mPas